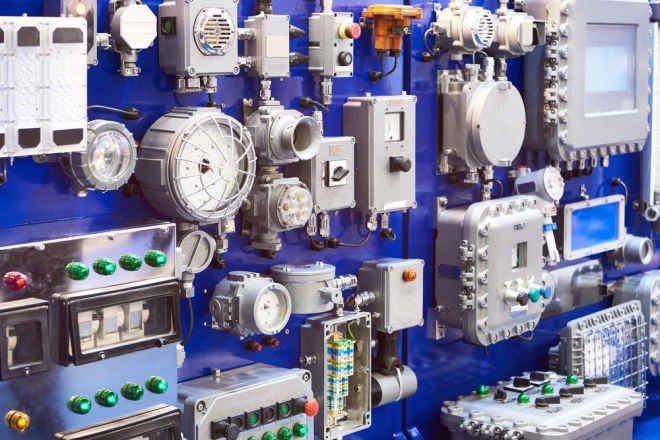

Almost 50 years ago this global leader in safety equipment started out with its first product – an explosion-proof electrical contactor. Since then, it has gone from strength to strength, adding to its impressive portfolio hundreds of thousands of products in multiple configurations to thousands of customers globally. They are now well trusted in industries such as Oil and Gas, Chemicals and Pharmaceuticals – industries with significant safety and regulatory requirements.

As is expected in this high-tech industry: 1) there is no room for ambiguity in material or product specification, 2) there are highly configurable complex products to correctly manufacture and ship, and 3) there are many manufacturing assets to keep operating on a day-to-day basis. This results in a large, diverse, multilingual portfolio of products and purchases, all passing daily through the existing SAP logistics system in multiple countries and languages.

One major challenge identified in managing these purchases optimally going forward is to agree on and implement a repeatable, practical classification of product categories. Using UNSPSC as a cornerstone, an international standard multilingual taxonomy from Refresh Desktop was selected, which can automate this task algorithmically. This software is to be used in 2024 by the existing shared services purchasing team, all trained remotely using Microsoft Teams.

Over the coming months, all materials and services, primarily free text SAP Purchase Order lines of Indirect Spend, will be commodity coded to UNSPSC, and then loaded back from Refresh Desktop in to the reporting system. The existing stock and make-to-order Material Master of finished and semi-finished products may also be de-duplicated / enhanced in a separate project, unlocking leaner manufacturing as well as significant new visibility in wall-to-wall spend across plants, countries and languages.