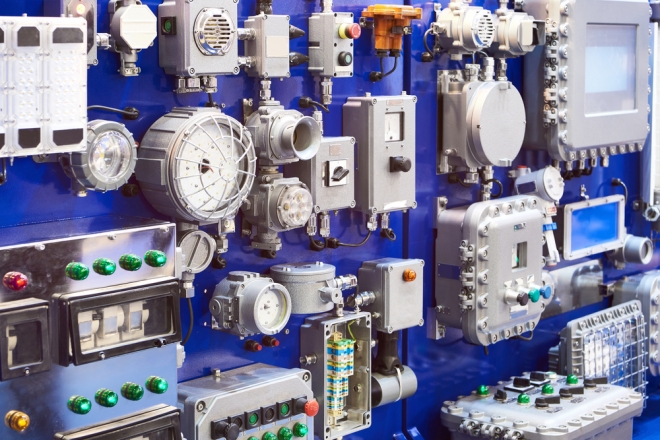

Almost 50 years ago this global leader in safety equipment started out with its first product – an explosion-proof electrical contactor. Since then, it has gone from strength to strength, adding to its impressive portfolio hundreds of thousands of products in multiple configurations to thousands of customers globally. As is expected in this high-tech industry there is no room for ambiguity in material or product specification, and there are highly configurable complex products to correctly manufacture and ship, resulting in a plethora of products in the supply chain system.

Over time this large set of products in the SAP material master had grown untidy to the point that it really needed a clean-up in order to safely sell, make-to-order and ship correct product. Until now it was a not a task that could be tackled using humans alone without a large internal effort. But thanks to the latest 2025 version of Refresh, its AI and the billions of feature embeddings in our chosen LLM this means that most of the products and product configurations are already "known" to the model and Refresh can automatically tease out professionally specified products attribute-by-attribute.

The existing stock and make-to-order Material Master of finished and semi-finished products are now to be rationalized, de-duplicated and enhanced this year, unlocking leaner order fulfilment as well as significant new visibility in wall-to-wall product availability across plants, countries and languages. Refresh is the catalyst for this that would not have been possible even a few years ago - exciting times.